Central Area Transmission System

| CATS pipeline | |

|---|---|

| Location | |

| Country | North Sea, United Kingdom |

| General direction | north-south-west |

| From | CATS Riser Platform |

| To | CATS processing terminal in Teesside, England |

| General information | |

| Type | natural gas |

| Partners | Antin Infrastructure Partners, ConocoPhillips, Eni |

| Operator | CATS Management Limited |

| Commissioned | 1993 |

| Technical information | |

| Length | 404 km (251 mi) |

| Maximum discharge | 1.7 billion standard cubic feet per day |

| CATS Gas Terminal | |

|---|---|

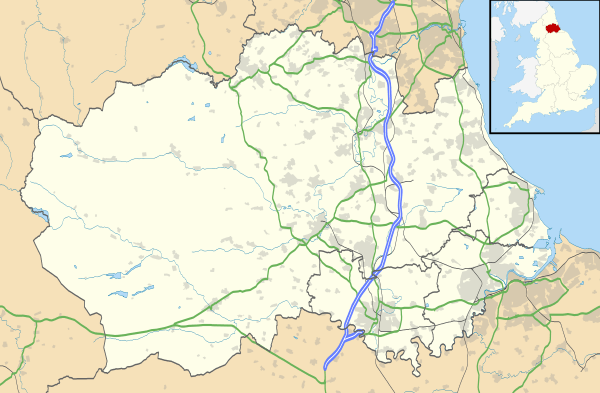

Location within County Durham | |

| Alternative names | CATS Terminal |

| General information | |

| Type | Gas terminal |

| Location | Seal Sands, Stockton-on-Tees, TS2 1UB |

| Coordinates | 54°36′37″N 1°10′41″W / 54.6103°N 1.17807°W |

| Elevation | 5 metres |

| Inaugurated | May 1993 |

| Owner | Antin Infrastructure Partners |

| Technical details | |

| Floor area | 70 acres (280,000 m2) |

The Central Area Transmission System (also known as CATS) is a natural gas transportation and processing system that transports gas through 404 kilometres of pipeline from the Central North Sea to a processing terminal at Teesside in the North East of England.

History

The receiving terminal site for the system was built between 1990 and 1993. It was originally run by Amoco. The CATS pipeline was completed in 1993, receiving gas from two of Amoco's fields: Everest and Lomond, now owned by BG.[1]

Together with the development of the Everest and Lomond fields, the project, which included the construction of an offshore riser, platform and pipeline, was one of the largest construction projects ever undertaken in the UK, second only to the Channel Tunnel at that time.

Due to increased demand within the Central North Sea, the decision was taken to provide a processing service to future users of the CATS pipeline, enabling delivery of their gas into the National Transmission System. This required the construction of a pipeline reception and gas treatment facility, and the CATS gas and liquids processing plant, comprising two processing trains, each with the capacity to handle around 17 million standard cubic metres of gas per day. The first of the new trains went into operation four months ahead of schedule in May 1997, and the second train was commissioned in 1998.

Plans for the site began from the discovery of BP's Lomond field in May 1972. In addition, other fields were discovered in the Central Graben Area of the North Sea.

In July 2007, the CATS pipeline was damaged by the anchor of the vessel 'Young Lady'. The pipeline was shut-in for two months.[2]

Route

The pipeline runs from the CATS Riser Platform adjacent to the BG Group operated Everest gas field in the Central North Sea, some 230 kilometres (140 mi) east of Aberdeen, to Teesside in England.[2] The pipeline reaches the shore at Coatham Sands near Redcar where it meets a Beach Valve Station. The gas travels under the River Tees in a 5-mile (8.0 km) long pipeline to the gas terminal.

The CATS pipeline was originally conceived to carry natural gas from the Everest and Lomond fields and was built oversized to accommodate future production from fields in the surrounding area. The CATS pipeline now transports gas from other fields such as Arbroath, Judy, Jade, Maria et al. through six connection points, known as 'tees' (T1 to T6), which are spaced at intervals along the pipeline, and nine CATS hubs.

Technical description

404 kilometres (250 mi) long natural gas pipeline The pipeline has a diameter of 36 inches (910 mm) and the capacity to handle up to 1.7 billion standard cubic feet of natural gas per day. The outside of the pipe is coated in concrete which gives added protection and also ensures that it remains firmly on the ocean bed while the gas is in transit. The inside of the pipe is lined with an epoxy film, which reduces friction and corrosion, thus maximising its capacity and prolonging the life of the pipeline.

Ownership

Antin Infrastructure Partners is the majority owner of CATS and one of the first non-oil and gas companies to own a significant part of UKCS midstream infrastructure.

A European private equity company focused on infrastructure investments, Antin acquired a controlling interest in CATS in July 2014. In April 2015, Antin agreed terms with BP to acquire their share in the CATS business, taking their stake to 99 per cent. The deal with BP completed on 17 December 2015.

Other partners with equity in CATS are Eni (0.3388 per cent) and ConocoPhillips (0.6630 per cent).

Antin owns its 99 per cent stake in CATS via a wholly owned subsidiary called CATS Management Limited. CATS Management Limited is accountable for setting the strategy and delivering safe and efficient operational and financial performance, along with growing the business.

CATS Management Limited appointed Wood Group as its operating partner. Wood Group provide the resources to manage the day-to-day operation of the CATS terminal and pipeline.

Antin's investment in CATS will bring new focus to the asset, and represents a new business model for the North Sea.

CATS Terminal

The Central Area Transmission System Terminal (also known as the CATS Terminal) is the connection point and processing facility for the CATS pipeline. It is based in Teesmouth at Seal Sands (borough of Stockton on Tees) on the North Sea coast, within a 29-hectare site. It is situated in the middle of Teesmouth's petrochemical area, between an oil terminal to the north, and a chemical works and the Teesside Oil Refinery (to the south).

It is not just a storage facility, but processes the gas through processing trains that ensure that its quality meets the requirements for entry to the National Transmission System (NTS). Natural Gas Liquids (NGLs) are removed and the processed natural gas is fiscally metered before leaving the terminal and being fed directly into the NTS. The NGLs are then separated into propane, butane and condensate.

In 2015, CATS delivered over 5 billion cubic metres of gas to UK markets, representing over 15% of UK gas production and over 7% of demand.

Gas processing

The gas terminal has the capacity to process about 34 million standard cubic metres of natural gas a day in two gas processing trains. The gas is dried in dehydration towers with a triethylene glycol cold finger regeneration system. One unit passes through a turboexpander and the other through a Joule–Thomson valve which reduces the pressure.

In the Low Temperature Separator, gas plant also produces the natural gas liquids propane, butane and liquid oil products (also known as natural gas condensate). These are fed into a fractionation system with a stabiliser column (where methane and ethane are removed), a de-propaniser and a de-butaniser.

The NGLs are transported by pipeline to petrochemical companies in the Teesmouth area. The propane and butane goes to the Phillips Norsea plant, and the condensate goes to Sabic North Tees on the former ICI site at Wilton and to the Tees Storage site owned by Vopak in Seal Sands.

px terminal

Since 1999, gas that is not processed by the CATS Terminal goes to the plant next-door operated by px Ltd. Also some of this gas goes through the px Ltd plant to the (former Enron) 1875MW Teesside power station next to the former ICI plant at Wilton, Redcar and Cleveland.

Distribution

The natural gas is metered, removed of hydrogen sulphide, and eventually enters the National Transmission System. It follows a four-mile (6 km) NTS feeder pipe to a pressure reduction station at Cowpen Bewley in Stockton-on-Tees, where gas can enter the Regional Transmission System. Further along the NTS feeder pipe, the gas enters the National Transmission System at Bishop Auckland.

The site has two tall chimneys and one taller flare stack. The site belongs to the Teesmouth Industry and Wildlife Partnership.

References

- ↑ "UK double for Aker Kvaerner". Upstream Online. NHST Media Group. 31 January 2005. Retrieved 4 October 2009.

- 1 2 Daniel Fineren (30 August 2007). "UK's CATS gas pipe reopens after repairs". Reuters. Retrieved 4 October 2009.