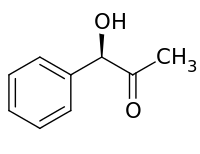

Phenylacetylcarbinol

| |

| Names | |

|---|---|

| IUPAC name

1-hydroxy-1-phenyl-propan-2-one | |

| Other names

l-PAC (R)-PAC | |

| Identifiers | |

| 1798-60-3 | |

| 3D model (Jmol) | Interactive image |

| ChemSpider | 8096061 |

| ECHA InfoCard | 100.001.824 |

| PubChem | 92733 |

| |

| |

| Properties | |

| C9H10O2 | |

| Molar mass | 150.18 g·mol−1 |

| Appearance | Powder |

| Density | 1.119 g/cm3 |

| Melting point | 39.47 °C (103.05 °F; 312.62 K) |

| Boiling point | 253 °C (487 °F; 526 K) |

| insoluble in water, freely soluble in alcohols, ether and aromatic solvents | |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

Phenylacetylcarbinol (PAC) is an organic compound that has two enantiomers, one with R- and one with S-configuration. (R)-PAC, which is commonly called l-PAC, is known as a precursor in the synthesis of pharmaceuticals such as ephedrine and pseudoephedrine.

Nomenclature

(R)-PAC or (R)-(−)-phenylacetylcarbinol is identical to l-PAC, referring to the outdated d/l system. [1] (R)-PAC is the levo-rotating isomer of phenylacetylcarbinol.

The IUPAC name of phenylacetylcarbinol is 1-hydroxy-1-phenylpropan-2-one. Synonyms are 1-hydroxy-1-phenyl-2-propanone and 1-Hydroxy-1-phenylacetone.

Production

(R)-PAC is widely synthesized by fermentation of benzaldehyde and dextrose. In this process, colonies of yeast (in particular, strains such as Candida utilis, Torulaspora delbrueckii, or Saccharomyces cerevisiae) are cultivated and added to a broth of water, dextrose, and the enzyme pyruvate decarboxylase in a vat. The yeast is left to grow for a period of time, after which the benzaldehyde is introduced into the broth. The yeast then ferments the benzaldehyde into (R)-PAC.[2]

The majority of L-PAC is generated in pharmaceutical plants in India, as an intermediate precursor in the production of pseudoephedrine.

There are also biochemical reactions where enzymes such as Acetohydroxyacid Synthase I [3] from E. coli condense pyruvate and benzaldehyde into R-PAC. Such methods have much higher conversion rates in comparison to the conventional yeast fermentation.[4]

References

- ↑ Rosche et al. Biotransformation of benzaldehyde into (R)-phenylacetylcarbinol by filamentous fungi or their extracts Appl Microbiol and Biotechnol; Vol. 57, Nr 3 (2001), pp 309-315; doi:10.1007/s002530100781

- ↑ LEKSAWASDI, N. "Kinetics and Modelling of Enzymatic Process for R-phenylacetylcarbinol (PAC) Production". University of New South Wales; Sydney, Australia. August, 2004; pp. 8-15.

- ↑ Acetolactate synthase

- ↑ Stanislav Engel et al, "Column flow reactor using acetohydroxyacid synthase I from Escherichia coli as catalyst in continuous synthesis of R-phenylacetyl carbinol" Department of Biotechnology Engineering, Ben-Gurion University of the Negev, Beer-Sheva 84105, Israel. November, 2004; pp. 733 - 740.