Moving bed biofilm reactor

Moving bed biofilm reactor (MBBR) is a type of wastewater treatment process that was first invented by Prof. Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s.[1] It was commercialized by Kaldnes Miljöteknologi (now called AnoxKaldnes and is owned by Veolia Water Technologies). There are over 700 wastewater treatment systems[2] (both municipal and industrial) installed in over 50 different countries. Currently, there are various different suppliers of MBBR systems.[3]

Process description

Overview

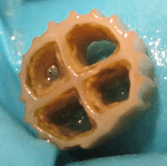

The MBBR system consists of an aeration tank (similar to a activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow. The carriers are made of a material with a density close to the density of water (1 g/cm3). For example, high-density polyetylen (HDPE) which have a density close to 0.95 g/cm3. The carriers will be mixed in the tank by the aeration system and thus will have good contact between the substrate in the influent wastewater and the biomass on the carriers.[2]

To prevent the plastic carriers to escape the aeration it is necessary to have a sieve on the outlet of the tank.

Advantages

The MBBR system is considered a biofilm process. Other conventional biofilm processes for wastewater treatment are called Trickling filter, Rotating biological contactor (RBC) and Biological Aerated Filter (BAF). Biofilm processes in general require less space than activated sludge systems because the biomass is more concentrated, and the efficiency of the system is less dependent on the final sludge separation. A disadvantage with other biofilm processes is that they experience clogging and build-up of headloss. As the MBBR system consists of floating carriers, the system is not susceptible to clogging and experience insignificant head loss.[1]

MBBR systems doesn't need a recycling of the sludge, which is the case with activated sludge systems.

The MBBR system is often installed as an retrofit of existing activated sludge tanks to increase the capacity of the existing system. The degree of filling of carriers can be adapted to the specific situation and the desired capacity. Thus an existing treatment plant can increase its capacity without increasing the footprint by constructing new tanks.

When constructing new MBBR systems the filling degree can be set to for example 40% in the beginning, and later be increased to 70% by filling more carriers. Examples of situations can be population increase in a city for a municipal wastewater treatment plant or increased wastewater production from a industrial factory.

Some other advantages compared to activated sludge systems are:[4]

- Higher effective Sludge Retention Time (SRT) which is favorable for nitrification

- Responds to Load Fluctuations without Operator intervention

- Lower sludge production.

- Less area required

- Resilient to toxic shock

- Process performance independent of secondary clarifier (due to the fact there is no sludge return line)

See also

References

- 1 2 Ødegaard, H.; Rusten, B.; Westrum, T. (1994-10-01). "A new moving bed biofilm reactor - applications and results". Water Science and Technology. 29 (10-11): 157–165. ISSN 0273-1223.

- 1 2 Ødegaard, Hallvard (2012). Vann- og Avløpsteknikk. Norsk Vann. ISBN 9788241403361.

- ↑ Haandel, Adrianus C. van; Lubbe, J. G. M. van der (2012-01-01). Handbook of Biological Wastewater Treatment: Design and Optimisation of Activated Sludge Systems. IWA Publishing. ISBN 9781780400006.

- ↑ Burton, Franklin; Tchobanoglous, George; Tsuchihashi, Ryujiro; Stensel, H. David; Inc, Metcalf & Eddy (2013-09-03). Wastewater Engineering: Treatment and Resource Recovery. McGraw-Hill Education. ISBN 9780073401188.