Plasma-facing material

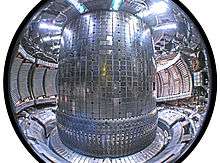

In nuclear fusion power research, the plasma-facing material (or materials) (PFM) is any material used to construct the plasma-facing components (PFC), those components exposed to the plasma within which nuclear fusion occurs, and particularly the material used for the lining or first wall of the reactor vessel.

Fusion reactor designs must consider three overall steps for energy generation:

- Generating heat through fusion,

- Capturing heat in the first wall,

- Transferring heat at a faster rate than capturing heat.

Currently, fusion reactor research focuses on improving efficiency and reliability in heat generation, capture, and rate of transfer. Generating electricity from heat is beyond the scope of current research due to existing efficient heat-transfer cycles, such as heating water to operate steam turbines that drive electrical generators.

Current fusion reactors are fueled by deuterium-tritium (D-T) fusion reactions, which produce high-energy neutrons that can damage the first wall.[1] Tritium is not a commonly available isotope due to its short half-life but can be bred by the nuclear reaction of lithium (Li) isotopes with high-energy neutrons that collide with the first wall.[2]

Requirements

Most magnetic confinement fusion devices (MCFD) consist of several key components in their technical designs, including:

- Magnet system: confines the deuterium-tritium fuel in the form of plasma and in the shape of a torus.

- Vacuum vessel: contains the core fusion plasma and maintains fusion conditions.

- First wall: positioned between the plasma and magnets in order to protect outer vessel components from radiation damage.

- Cooling system: removes heat from the confinement and transfers heat from the first wall.

The core fusion plasma must not actually touch the first wall. ITER and many other current and projected fusion experiments, particularly those of the tokamak and stellarator designs, use intense magnetic fields in an attempt to achieve this, although plasma instability problems remain. Even with stable plasma confinement, however, the first wall material would be exposed to a neutron flux higher than in any current nuclear power reactor, which leads to two key problems in selecting the material:

- It must withstand this neutron flux for a sufficient period of time to be economically viable.

- It must not become sufficiently radioactive so as to produce unacceptable amounts of nuclear waste when lining replacement or plant decommissioning eventually occurs.

The lining material must also:

- Allow the passage of a large heat flux.

- Be compatible with intense and fluctuating magnetic fields.

- Minimize contamination of the plasma.

- Be produced and replaced at a reasonable cost.

Some critical plasma-facing components, such as and in particular the divertor, are typically protected by a different material than that used for the major area of the first wall.[3]

Proposed materials

Materials currently in use or under consideration include:

- Boron carbide.[4][5]

- Graphite.

- Carbon fibre composite (CFC).[5]

- Beryllium.

- Tungsten.

- Molybdenum.

- Lithium.

Multi-layer tiles of several of these materials are also being considered and used, for example:

- A thin molybdenum layer on graphite tiles.

- A thin tungsten layer on graphite tiles.

- A tungsten layer on top of a molybdenum layer on graphite tiles.

- A boron carbide layer on top of CFC tiles.[5]

- A liquid lithium layer on graphite tiles.[6]

- A liquid lithium layer on top of a boron layer on graphite tiles.[7]

- A liquid lithium layer on tungsten-based solid PFC surfaces or divertors.[8]

Graphite was used for the first wall material of the Joint European Torus (JET) at its startup (1983), in Tokamak à configuration variable (1992) and in National Spherical Torus Experiment (NSTX, first plasma 1999).[9]

Beryllium was used to reline JET in 2009 in anticipation of its proposed use in ITER.[10]

Tungsten is used for the divertor in JET, and will be used for the divertor in ITER.[10] It is also used for the first wall in ASDEX Upgrade.[11] Graphite tiles plasma sprayed with tungsten were used for the ASDEX Upgrade divertor.[12]

Molybdenum is used for the first wall material in Alcator C-Mod (1991).

Liquid lithium (LL) used to coat the PFC of the Tokamak Fusion Test Reactor (TFTR, 1996).[6]

Considerations

Development of satisfactory plasma-facing materials is one of the key problems still to be solved by current programs.[13][14]

Plasma-facing materials can be measured for performance in terms of:[7]

- Power production for a given reactor size.

- Cost to generate electricity.

- Self-sufficiency of tritium production.

- Availability of materials.

- Design and fabrication of the PFC.

- Safety in waste disposal and in maintenance.

The International Fusion Materials Irradiation Facility (IFMIF) will particularly address this. Materials developed using IFMIF will be used in DEMO, the proposed successor to ITER.

French Nobel laureate in physics, Pierre-Gilles de Gennes said of nuclear fusion, "We say that we will put the sun into a box. The idea is pretty. The problem is, we don't know how to make the box."[15]

Recent developments

Solid plasma-facing materials are known to be susceptible to damage under large heat loads and high neutron flux. If damaged, these solids can contaminate the plasma and decrease plasma confinement stability. In addition, radiation can leak through defections in the solids and contaminate outer vessel components.[1]

Liquid metal plasma-facing components that enclose the plasma have been proposed to address challenges in the PFC. In particular, liquid lithium (LL) has been confirmed to have various properties that are attractive for fusion reactor performance.[1]

Lithium

Lithium (Li) is an alkali metal with a low Z (atomic number). Li has a low first ionization energy of ~ 6 eV and is highly chemically reactive with ion species found in the plasma of fusion reactor cores. In particular, Li readily forms stable lithium compounds with hydrogen isotopes, oxygen, carbon, and other impurities found in D-T plasma.[1]

The fusion reaction of D-T produces charged and neutral particles in the plasma. The charged particles remain magnetically confined to as a plasma. The neutral particles are not magnetically confined and will move toward the boundary between the hotter plasma and the colder PFC. Upon reaching the first wall, both neutral particles and charged particles that escaped the plasma become cold neutral particles in gaseous form. An outer edge of cold neutral gas is then "recycled", or mixed, with the hotter plasma. A temperature gradient between the cold neutral gas and the hot plasma is believed to be the principal cause of anomalous electron and ion transport from the magnetically confined plasma. As recycling decreases, the temperature gradient decreases and plasma confinement stability increases. With better conditions for fusion in the plasma, the reactor performance increases.[2]

Initial use of lithium in 1990s was motivated by a need for a low-recycling PFC. In 1996, ~ 0.02 grams of lithium coating was added to the PFC of TFTR, resulting in the fusion power output and the fusion plasma confinement to improve by a factor of two. On the first wall, lithium reacted with neutral particles to produce stable lithium compounds, resulting in low-recycling of cold neutral gas. In addition, lithium contamination in the plasma tended to be well below 1%.[1]

Since 1996, these results have been confirmed by a large number of magnetic confinement fusion devices (MCFD) that have also used lithium in their PFC, for example:[1]

- TFTR (US), CDX-U (2005)/LTX(2010) (US), CPD (Japan), HT-7 (China), EAST (China), FTU (Italy).

- NSTX (US), T-10 (Russia), T-11M (Russia), TJ-II (Spain), RFX (Italy).

The primary energy generation in fusion reactor designs is from the absorption of high-energy neutrons. Results from these MCFD highlight additional benefits of liquid lithium coatings for reliable energy generation, including:[1][2][6]

- Absorb high-energy, or fast-moving, neutrons. About 80% of the energy produced in a fusion reaction of D-T is in the kinetic energy of the newly produced neutron.

- Convert kinetic energies of absorbed neutrons into heat on the first wall. The heat that is produced on the first wall can then be removed by coolants in ancillary systems that generate electricity.

- Self-sufficient breeding of tritium by nuclear reaction with absorbed neutrons. Neutrons of varying kinetic energies will drive tritium-breeding reactions.

- Liquid lithium

Newer developments in liquid lithium are currently being tested, for example:[7][8]

- Coatings made of increasingly complex liquid lithium compounds.

- Multi-layered coatings of LL, B, F, and other low-Z metals.

- Higher density coatings of LL for use on PFC designed for greater heat loads and neutron flux.

See also

- International Fusion Materials Irradiation Facility#Background information.

- Lithium Tokamak Experiment.

References

- 1 2 3 4 5 6 7 Lithium As Plasma Facing Component for Magnetic Fusion Research. Ono. 2012 retrieved 1 November 2015

- 1 2 3 Molokov, S. S.; Moreau, R.; Moffatt K. H. Magnetohydrodynamics: Historical Evolution and Trends, p. 172-173.

- ↑ http://www.apam.columbia.edu/courses/apph4990y_ITER/Divertor%20Presentation%20-%20Stoafer.pdf retrieved 11 September 2012

- ↑ http://www.ipp.mpg.de/ippcms/eng/for/projekte/pfmc/meilensteine/B4C_Panels.html retrieved 10 September 2012

- 1 2 3 Mechanical fracture of CFC first wall tiles is found. The first application of B4C-converted CFC tiles (surface-boronized ones using conversion method) is also shown., retrieved 11 September 2012

- 1 2 3 http://www.pppl.gov/sites/pppl/files/LTX.pdf retrieved 30 October 2015 The Lithium Tokamak Experiment (LTX).

- 1 2 3 Kaita, R.; Berzak, L.; Boyle, D. (2010-04-29) Experiments with liquid metal walls: Status

of the lithium tokamak experiment, Fusion Engineering and Design 85 (6): 874-881. doi:10.1016/j.fusengdes.2010.04.005.

- 1 2 Recent progress in the NSTX/NSTX-U lithium programme and prospects for reactor-relevant liquid-lithium based divertor development., retrieved 1 November 2015

- ↑ http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber=849793&url=http%3A%2F%2Fieeexplore.ieee.org%2Fxpls%2Fabs_all.jsp%3Farnumber%3D849793 retrieved 10 September 2012

- 1 2 http://news.sciencemag.org/sciencenow/2012/08/how-to-line-a-thermonuclear-reac.html retrieved 12 September 2012

- ↑ http://www.ipp.mpg.de/de/for/projekte/pfmc/results2000/w-coatings.html retrieved 10 September 2012 Examples of Test Coatings for the ASDEX Upgrade Tungsten First Wall

- ↑ http://iopscience.iop.org/0741-3335/38/12A/013 retrieved 9 September 2012

- ↑ Evans, Ll. M.; Margetts, L.; Casalegno, V.; Lever, L. M.; Bushell, J.; Lowe, T.; Wallwork, A.; Young, P.; Lindemann, A. (2015-05-28). "Transient thermal finite element analysis of CFC–Cu ITER monoblock using X-ray tomography data". Fusion Engineering and Design. 100: 100–111. doi:10.1016/j.fusengdes.2015.04.048.

- ↑ Evans, Ll. M.; Margetts, L.; Casalegno, V.; Leonard, F.; Lowe, T.; Lee, P. D.; Schmidt, M.; Mummery, P. M. (2014-06-01). "Thermal characterisation of ceramic/metal joining techniques for fusion applications using X-ray tomography". Fusion Engineering and Design. 89 (6): 826–836. doi:10.1016/j.fusengdes.2014.05.002.

- ↑ Michio Kaku, Physics of the Impossible, p.46-47

External links

- http://www.ipp.mpg.de/ippcms/eng/for/projekte/pfmc/index.html Max Planck Institute project page on PFM

- http://www.ipp.mpg.de/ippcms/eng/for/veranstaltungen/konferenzen/archiv/2011/03pfmc-13/index.html 13th International Workshop on Plasma-Facing Materials and Components for Fusion Applications / 1st International Conference on Fusion Energy Materials Science

- "Development of W coatings for fusion applications". Fusion Engineering and Design. 86: 1677–1680. doi:10.1016/j.fusengdes.2011.04.031. Retrieved 10 September 2012.

Abstract: The paper gives a short overview on tungsten (W) coatings deposited by various methods on carbon materials (carbon fibre composite – CFC and fine grain graphite – FGG). Vacuum Plasma Spray (VPS), Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)... A particular attention is paid to the Combined Magnetron Sputtering and Ion Implantation (CMSII) technique, which was developed during the last 4 years from laboratory to industrial scale and it is successfully applied for W coating (10–15 μm and 20–25 μm) of more than 2500 tiles for the ITER-like Wall project at JET and ASDEX Upgrade.... Experimentally, W/Mo coatings with a thickness up to 50 μm were produced and successfully tested in the GLADIS ion beam facility up to 23 MW/m2. Keywords: Tungsten coating; Carbon fibre composite (CFC); ITER-like wall; Magnetron sputtering; Ion implantation