Rise in Core

The Rise in Core (RIC) method is an alternate reservoir wettability characterization method described by S. Ghedan and C. H. Canbaz in 2014. The method enables to estimate all wetting regions like strongly water wet, water wet, intermediate water and oil wet, oil wet and strongly oil wet regions in relatively quick, accurate measurements of wettability in terms of Contact angle and not wettability index as other methods do.

The method is easy to use and requires no complex equipment. During the RIC experiments, core samples saturated with selected reservoir fluid are subjected to imbibition from a second reservoir fluid. RIC wettability measurements compared with modified - Amott test[1] and USBM measurements by using core plug pairs from different heights of a thick carbonate reservoir. Results showed good coherence and RIC technique proved to be much simpler, faster to perform and much easier to analyze and interpret than other methods.[2]

Cut-off values instead of a wettability index

Treiber et al.[3] used the water advancing contact angle to estimate the wettability of fifty five oil reservoirs. In the study, deoxygenated synthetic formation brine and dead anaerobic crudes were tested on quartz and calcite crystals at reservoir temperature. Contact angles from 0 to 75 degrees were deemed water wet, 75 to 105 degrees as intermediate wettability, and 105 to 180 degrees as oil wet. Although the range of wettabilities was divided into three regions, it should be strongly emphasized that these are arbitrary divisions. The wettability of different reservoirs can vary within the broad spectrum from strongly-water wet to strongly-oil wet. Morrow[4] described two initial conditions as reference and non-reference for calculating cut-off values by using advancing and receding contact angles and spontaneous imbibition data. Limiting value between water wet and intermediate zones was described as 62 degree. Similarly, cut-off values for advancing contact angle is described as 0 to 62 degrees for water wet region, 62 to 133 degrees for Intermediate-wet zone, and 133 to 180 degrees for Oil wet zone. Chilingar and Yen[5] examined extensive research work on 161 limestone, dolomitic limestone, calcitic dolomite, and dolomite cores. Cut-off values classified as 160 to 180 degrees for strongly oil wet, 100 to 160 degrees for oil wet, 80 to 100 degrees intermediate wet, 80 to 20 degrees water wet and 0 to 20 strongly water wet.

Rise in Core uses a combination of Chilingar et al. and Morrow wettability cut-off criteria. The contact angle range 80 – 100 degrees indicate neutral-wetness, the range 100 – 133 degrees indicate slight-oil wetness, the range 133 – 160 degrees indicate oil-wetness while the range 160- 180 degrees indicate strongly oil-wetness. The range 62 – 80 degrees indicate slight water wetness, the range 20 – 62 degrees indicate, water-wetness, while the range 0 – 20 degrees indicate strong water-wetness.

Technique

Rise In Core (RIC) wettability characterization technique is based on a modified form of the Washburn's equation (1921). The technique enables relatively quick and accurate measurements of wettability in terms of contact angle with requiring no complex equipment. The method is applicable for any set of reservoir fluids, on any type of reservoir rock and at any heterogeneity level. It characterizes wettability across the board from strongly water to strongly oil wet conditions.[6]

The step of deriving the modified form of Washburn Equation for a rock/liquid/liquid system comprises acquiring a Washburn equation for a rock/air/liquid system, and wherein Washburn Equation for rock/air/liquid system is represented by;

(Eq.1)

Herein, "t" is a penetration rate of liquid into a porous sample, "μ" is a viscosity of the liquid, "ρ" is a density of the liquid, "γ" is a surface tension of the liquid, "θ" is contact angle made by the liquid, and "m" is a mass of the liquid penetrated into the porous sample, and "C" is a constant of characterization of the porous sample; evaluating a value of "γos" using a young’s equation for a rock surface/water/air system (Figure 2) and a value of "γws" using young’s equation for a liquid/liquid/rock system is represented by below equation;

(Eq.2)

Wherein "γow" surface tension between oil and water system, "γos" is a surface tension between oil and solid system and "γws" is a surface tension between water and solid system. Using Young’s equation for a rock surface/ water/ air system and substituting in equation (2) to obtain equation 3;

(Eq. 3)

Rearranging equation (1) to factor out γLV to obtain an equation (4), and wherein γLV a liquid-vapor surface tension is;

(Eq. 4)

Realizing that γLV (liquid-vapor surface tension) is equivalent to γo (oil-air surface tension), or γw (water-air surface tension), substitute equation (4) in equation (3) and cancelling out similar terms to obtain equation (5), and wherein equation (5) is;

(Eq. 5)

Herein, γLV is liquid-vapor surface tension, γois oil-air surface tension, γw is water-air surface tension, µo is viscosity of oil and µw is viscosity of water. cosθwo is contact angle between water and oil; representing a relationship between a mass of water imbibed into the core sample and a mass of oil imbibed in the core sample with an equation (6), wherein the equation (6) is;

(Eq. 6)

ρw is density of water and Vw is volume of water imbibed, ρo is density of oil and Vo is volume of oil imbibed, the amount of water imbibed and amount of oil imbibed under gravity are same; and air behaves as a strong non-wetting phase in both of an oil/air/solid and a water/air/solid systems, thereby indicating that both oil and water behaves as a strong wetting phases, resulting in an equal air/oil and air/water capillary forces for a same porous media and for a given pore size distribution, thus, a mass change of a core sample due to a water imbibition is equal to a mass change of a core sample as a due to an oil imbibition because water or oil penetration of the porous media at any time is a function of a balance between a gravity and a capillary forces. Mass of water imbibed into a core sample is approximately equal to a mass of oil imbibed in the core sample core samples of a same rock type and dimensions, and for equal capillary forces;

Cancelling out g in equation(6) represented to obtain an equation (7);

(Eq. 7)

Which means that;

(Eq. 8)

Herein, mw is mass of water and mo is mass of oil. Factoring out from Eq. 5 to obtain Eq. 9, gives Modified Washburn Equation;

(Eq. 9)

θ12 is the contact angle of liquid/liquid/rock system, and μ1 is a viscosity of oil phase, and μ2 is a viscosity of water phase, ρ1 is density of oil phase in g/cm³, ρ2 is density of water phase in g/cm³, m is mass of fluid penetrated into a porous rock, t is time in min and γ_L1L2 is a surface tension between an oil and a water in dyne/cm, and ∁ is a characteristic constant of the porous rock.

Experimental setup and procedure

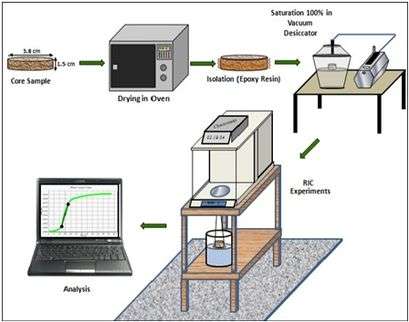

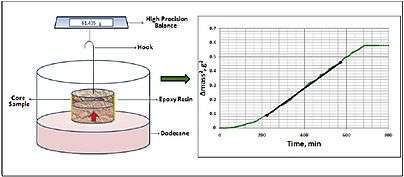

Schematic view and experimental setups of RIC wettability testing method is described in Figure 1. All core plugs divided to 3-4 core samples, each of 3.8 cm average diameter and 1.5 cm in length. Lateral area of each core sample sealed by epoxy resin to ensure one-dimensional liquid penetration into the core by the imbibition process. A hook is mounted on top side of the core sample.

The RIC setup includes a beaker to host the imbibing fluid. A thin rope connects the core sample to a high precision balance (0.001 gm accurate). Hanging core sample is positioned with the bottom part of the sample as barely touching the imbibing fluid in the beaker. Relative saturation as well as mass of core samples starts to change by imbibition process. A computer connected to balance continuously monitors the mass change of core sample by time. Plots of squared mass change versus time are generated.

Determination of "C" constant

RIC experiment is first performed with a n-dodecane/air/rock system to determine the constant ∁ of the Washburn Equation. N-dodecane imbibes into one of the core samples and imbibition curve recorded Figure 4. Dodecane is an alkane that has very low surface energy making it to be very strongly wetting the rock sample in the presence of air, with contact angle, θ equals to zero. Constant ∁ is determined by having contact angle value for dodecane/air/rock system, determining physical properties of n-dodecane (ρ,μ,γ) and rearranging equation 1;

(Eq. 10)

Experiment

The second step of the RIC experimental process is to saturate neighboring core sample with crude oil, and subjected the sample to formation water imbibition. Applying the slope of the RIC curve , fluid properties of oil/brine system (ρ,μ,γ) and the ∁ value determined from the neighboring core sample into Eq. 9 to calculate the contact angle, θ.

It has been proved by Ghedan and Canbaz and patented that the RIC method is an alternate method to Amott and USBM methods and it efficiently characterizes Reservoir Wettability.[7]

References

- ↑ 14. Amott, E.: "Observations related to Wettability of Porous Rock" Trans., AIME (1959) 216, 156-162.

- ↑ Inventors : S. Ghedan, C.H. Canbaz, Patent Title, "Rise in Core Wettability Characterization Method", Patent No. US 20120136578, Publication date: 2014-07-01

- ↑ Treiber, L., Archer, D., and Owens, W.: "Laboratory Evaluation of the Wettability of Fifty Oil Producing Reservoirs". SPEJ (Dec. 1972) 531-540.

- ↑ Morrow, N., Ma, S., Zhou, X., and Zhang, X.: "Characterization of Wettability from Spontaneous Imbibition Measurements". Paper CIM 94-47, Presented at the 45th Annual Technical Meeting for the Petroleum Society of CIM, Calgary, June, 12-15, 1994.

- ↑ Chilingar, G.V. and Yen, T. F.:"Some Notes on Wettability and Relative Permeabilities of Carbonate Reservoir Rocks", II, Energy Sources, 7, No.1, 67-75, 1983.

- ↑ Ghedan, S. G., Canbaz, C.H., Boyd, D., Mani, G., Haggag, M., “Wettability Profile of a Thick Carbonate Reservoir by the New Rise in Core Wettability Characterization Method”, SPE # 138697, ADIPEC 2010, Abu Dhabi, UAE, Nov 1-4, 2010.

- 1 2 Canbaz, C.H., Ghedan, S.G., "Theory and Experimental Setup of the New Rise In Core Reservoir Wettability Measurement Technique" IPTC #17659, IPTC, Doha, Qatar, January, 2014.