Trisilane

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Trisilane | |||

| Identifiers | |||

| 7783-26-8 | |||

| 3D model (Jmol) | Interactive image | ||

| ChemSpider | 122661 | ||

| ECHA InfoCard | 100.132.113 | ||

| UN number | 3194 | ||

| |||

| |||

| Properties | |||

| H8Si3 | |||

| Molar mass | 92.32 g·mol−1 | ||

| Appearance | Colourless liquid | ||

| Odor | Unpleasant | ||

| Density | 0.743 g cm−3 | ||

| Melting point | −117 °C (−179 °F; 156 K) | ||

| Boiling point | 53 °C (127 °F; 326 K) | ||

| Vapor pressure | 12.7 kPa | ||

| Hazards | |||

| Main hazards | Pyrophoric | ||

| S-phrases | S3 | ||

| Flash point | < −40 °C (−40 °F; 233 K) | ||

| < 50 °C (122 °F; 323 K) | |||

| Related compounds | |||

| Related hydrosilicons |

Disilane Disilyne Silane Silylene | ||

| Related compounds |

Propane | ||

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |||

| Infobox references | |||

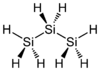

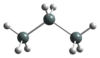

Trisilane /traɪsaɪleɪn/ is a three-silicon silane. It has the chemical formula Si3H8, and is a liquid at standard temperature and pressure. It is a silicon analogue of propane.

Discovery

Trisilane was discovered in 1916 by Carl Somieski and Alfred Stock while investigating the reaction between hydrochloric acid and magnesium silicide. This reaction had been explored as early as 1857 by Friedrich Woehler and Heinrich Buff, and further investigated by Henri Moissan and Samuel Smiles in 1902. The decomposition of magnesium silicide produces a variety of silanes, but trisilane was first explicitly identified by Somieski and Stock. Initially called silicopropane, trisilane was identified as a member of a series analogous to alkanes, including silicobutane (Si4H10), silicopentane (Si5H12), and silicohexane (Si6H14).

Synthesis

Trisilane is a trace product of the reaction between SiH2 and HCl. This reaction is done using infrared lasers. The laser was set up in a stainless steel cylindrical cell with the laser perpendicular to the mass spectrometer. Trisilane can also be produced by using the Schlesinger process. This process reacts lithium aluminium hydride with octachlorotrisilane in 1-butoxybutane. Trisilane is also yielded by thermal decomposition of monosilane and disilane at higher temperatures as demonstrated by Bowrey, Purnell and Walsh in the sixties.

Decomposition

The decomposition of trisilane is a 1,2 hydrogen shift that produces disilanes, normal and isotetrasilanes, and normal and isopentasilanes. The proposed mechanism involves the low lying unoccupied orbitals of 4s and 3d on Si. [1]

Application

Carrier

Trisilane is being explored as a silicon carrier for plasma guns. This process can apply silicon in thin layers for semiconductors and similar applications. One of the more promising applications would be an inexpensive process to make solar panels. Trisilane is liquid at 20°C and thus has more silicon per flow rate than gaseous silicon carriers. Depending on the application, a mixture of gases, liquids and/or solids may be desirable. Altering the composition of the carrier allows for a variation in the film thickness and droplets from the spray that can solidify on the material, which are called coins. The formation of coins is why a carrier must be carefully selected, gaps between the coins can lead to an incomplete application of silicon to the material. [2]

Nanowires

Silicon is useful as a semiconductor in many computer hardware applications. It is stable and performs well in those circumstances. Due to the nature of silicon, it performs better on smaller scales, which makes it even more desirable to use for nanowires. Previous methods for the growth of nanowires involves a supercritical fluid-liquid-solid (SFLS) material in organic solvents, temperatures above 400 °C, and pressures above 100 bar. High energy requirements, specialized equipment and undesirable byproducts can limit the production of nanowires. Methods employing trisilane have many advantages over the SFLS method. Not only can they be done at atmospheric pressure, they can be done at 363 °C with a bismuth seed or 264 °C with a gold seed. The trisilane method is a solution-liquid-solid method (SLS) and relatively clean with little amorphous or particulate byproducts. Though this process is still in its infancy, the advantages are worth exploring. Further experimentation will be required to fine-tune to process, but preliminary results look promising.[3]

References

- ↑ Kinetics of the Thermal Decomposition of Methyldisilane and Trisilane. A.J. Vanderwielen, M.A. Ring, H.E. O’Neal. JACS, 97:5, March 5, 1975

- ↑ United States Patent Application Publication. Pub No. US 2012/0252190 A1, OCT, 4, 2012. Zehavi et al.

- ↑ "Solution-Liquid-Solid (SLS) Growth of Silicon Nanowires". Andrew T. Heitsch, Dayne D. Fanfair, Hsing-Yu Taun, and Brian A. Korgel. JACS, March, 29, 2008.