Methyl methacrylate

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Methyl 2-methylprop-2-enoate | |

| Other names

Methyl 2-methylpropenoate methyl methacrylate MMA 2-(methoxycarbonyl)-1-propene | |

| Identifiers | |

| 80-62-6 | |

| 3D model (Jmol) | Interactive image |

| ChEBI | CHEBI:34840 |

| ChEMBL | ChEMBL49996 |

| ChemSpider | 6406 |

| ECHA InfoCard | 100.001.180 |

| KEGG | C14527 |

| RTECS number | OZ5075000 |

| UNII | 196OC77688 |

| |

| |

| Properties | |

| C5H8O2 | |

| Molar mass | 100.12 g·mol−1 |

| Appearance | Colorless liquid |

| Odor | acrid, fruity[1] |

| Density | 0.94 g/cm3 |

| Melting point | −48 °C (−54 °F; 225 K) |

| Boiling point | 101 °C (214 °F; 374 K) |

| 1.5 g/100 ml | |

| Vapor pressure | 29 mmHg (20°C)[1] |

| Viscosity | 0.6 cP at 20 °C |

| Structure | |

| 1.6–1.97 D | |

| Hazards | |

| Main hazards | Flammable |

| Safety data sheet | See: data page Methyl methacrylate MSDS |

| Flash point | 2 °C (36 °F; 275 K) |

| 435 °C (815 °F; 708 K) | |

| Explosive limits | 1.7%-8.2%[1] |

| Lethal dose or concentration (LD, LC): | |

| LC50 (median concentration) |

18750 ppm (rat, 4 hr) 4447 ppm (mouse, 2 hr) 3750 ppm (rat) 4808 ppm (mammal)[2] |

| LCLo (lowest published) |

4400 ppm (rat, 8 hr) 4400 ppm (rabbit, 8 hr) 4207 ppm (rabbit, 4.5 hr) 4567 ppm (guinea pig, 5 hr)[2] |

| US health exposure limits (NIOSH): | |

| PEL (Permissible) |

TWA 100 ppm (410 mg/m3)[1] |

| REL (Recommended) |

TWA 100 ppm (410 mg/m3)[1] |

| IDLH (Immediate danger) |

1000 ppm[1] |

| Supplementary data page | |

| Refractive index (n), Dielectric constant (εr), etc. | |

| Thermodynamic data |

Phase behaviour solid–liquid–gas |

| UV, IR, NMR, MS | |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

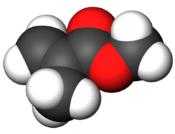

Methyl methacrylate (MMA) is an organic compound with the formula CH2=C(CH3)COOCH3. This colourless liquid, the methyl ester of methacrylic acid (MAA) is a monomer produced on a large scale for the production of poly(methyl methacrylate) (PMMA).

Production and properties

The compound is manufactured by several methods, the principal one being the acetone cyanohydrin (ACH) route. ACH is produced by condensation of acetone and hydrogen cyanide. The cyanohydrin is hydrolyzed in the presence of sulfuric acid to a sulfate ester of the methacrylamide, Methanolysis of this ester gives ammonium bisulfate and MMA. Although widely used, the ACH route coproduces substantial amounts of ammonium sulfate.

- (CH3)2CO + HCN → (CH3)2C(OH)CN

- (CH3)2C(OH)CN + H2SO4 → (CH3)2C(OSO3H)C(O)NH2.

In fact the sulfate ester of the amide is initially produced as an adduct with sulfuric acid ((CH3)2C(OSO3H)C(O)NH2. H2SO4), which is removed in a cracking step. The sulfate ester is then methanolyzed (reacted with methanol):

- (CH3)2C(OSO3H)C(O)NH2 + CH3OH → CH2 =C(CH3)C(O)OCH3 + NH4HSO4

As indicated in the last reaction, each kilogram of methyl methacrylate produced yields 2.5 kg of ammonium hydrogen sulphate, Disposal of this salt is energy intensive. This technology affords more than 3 billion kilograms per year.

The economics of the ACH route have been heavily optimized.[3][4]

Other routes to MMA

Given the scale of production, many methods have been developed starting from diverse two- to four-carbon precursors.[5]

From propionaldehyde

Ethylene is first hydroformylated to give propanal, which is then condensed with formaldehyde to produce methacrolein, The condensation is catalyzed by a secondary amine. Air oxidation of methacrolein to methacrylic acid completes the synthesis of the acid:[3]

- CH3CH2CHO + HCHO → CH2=C(CH3)–CHO + H2O

- CH2=CH(CH3)–CHO + O → CH2=C(CH3)–CO2H + H2O

Methyl propionate routes

The first stage involves hydroesterification of ethylene to produce methyl propionate (MeP):

- C2H4 + CO + CH3OH → CH3CH2CO2CH3

The first step in the process, the MeP synthesis reaction, is done in a continuous-stirred tank reactor under moderate conditions of temperature and pressure using proprietary agitation and gas-liquid mixing arrangement.

In the second reaction step, MeP is condense with formaldehyde in a single heterogeneous reaction step to form MMA:[6]

- CH3CH2CO2CH3 + CH2O → CH3(CH2)CCO2CH3 + H2O

The reaction of MeP and formaldehyde takes place over a fixed bed of catalyst. This catalyst, caesium oxide on silica, achieves good selectivity to MMA from MeP. The formation of a small amount of heavy, relatively involatile compounds poisons the catalyst. The coke is easily removed and catalyst activity and selectivity restored by controlled, in-situ regeneration. The reactor product stream is separated in a primary distillation so that a crude MMA product stream, free from water, MeP and formaldehyde, is produced. Unreacted MeP and water are recycled via the formaldehyde dehydration process. Pure MMA (>99.9%) is produced from the crude MMA in a series of vacuum distillations and separations. In all cases, the separated streams are returned to the process; there is only one (small) heavy ester purge stream. This is readily disposed of in a thermal oxidizer with heat recovered for use in the process.

In the fourth quarter of 2008, Lucite international commissioned its ‘first in class’ Alpha MMA plant based on Jurong Island in Singapore. This process plant is 30-40% cheaper to build and run than conventional systems, produces virtually no waste and the feedstocks can even be made from biomass.

From isobutyric acid

As developed by Atochem and Röhm, isobutyric acid is produced by hydrocarboxylation of propene, using HF as a catalyst:

- CH2=CHCH3 + CO + H2O → (CH3)2CHCO2H

Oxidative dehydrogenation of the isobutyric acid yields methacrylic acid. Metal oxides catalyse this process:[3]

- (CH3)2CHCO2H + O → CH2=C(CH3)CO2H + H2O

Methyl acetylene (propyne) process

Using Reppe chemistry, methyl acetylene is converted to MMA. As developed by Shell, this process produces MMA in one step reaction with 99% yield with a catalyst derived from palladium acetate, phosphine ligands, and Bronsted acids as catalyst:[3]

- CH≡CCH3 + CO + CH3OH → CH2=C(CH3)CO2CH3

Isobutylene route

The reactions by the direct oxidation method consist of two-step oxidation of isobutylene or TBA with air to produce methacrylic acid and esterification by methanol to produce MMA.[3]

- CH2=C–(CH3)2 (or (CH3)3C–OH) + O2 → CH2=C(CH3)–CHO + H2O

- CH2=C(CH3)–CHO + 1⁄2 O2 → CH2=C(CH3)–COOH

- CH2=C(CH3)–COOH + CH3OH → CH2=C(CH3)–COOCH3 + H2O

Methacrylonitrile (MAN) process

MAN can be produced by ammoxidation from isobutylene. This step is analogous to the industrial route to acrylonitrile, a related commodity chemical.

- (CH3)2C=CH2 + NH3 + 3⁄2 O2 → CH2=C(CH3)CN + 4 H2O

MAN can be hydrated by sulfuric acid to methacrylamide:

- CH2=C(CH3)CN + H2SO4 + H2O → CH2=C(CH3)–CONH2·H2SO4

- CH2=C(CH3)–CONH·H2SO4 + CH3OH → CH2=C(CH3)COOCH3 + NH4HSO4

Mitsubishi Gas Chemicals proposed that MAN can be hydrated to methacrylamide without using sulfuric acid and is then esterified to obtain MMA by methylformate.[3]

- CH2=C(CH3)CN + H2O → CH2=C(CH3)–CONH2

- CH2=C(CH3)–CONH2 + HCOOCH3 → CH2=C(CH3)COOCH3 + HCONH2

- HCONH2 → NH3 + CO

Esterification of methacrolein

Asahi Chemical developed a new process based on direct oxidative esterification of methacrolein, which does not produce by-products such as ammonium bisulfate. The raw material is tert-butanol, as in the direct oxidation method. In the first step, methacrolein is produced in the same way as in the direct oxidation process by gas phase catalytic oxidation, is simultaneously oxidized and is esterified in liquid methanol to get MMA directly.[3]

- CH2=C(CH3)–CHO + CH3OH + 1⁄2 O2 → CH2=C(CH3)–COOCH3 + H2O

Escambia process

A process using isobutylene as a raw material has been commercially employed by Escambia Co. for a short period of time. Isobutylene is oxidized to provide α-hydroxy isobutyric acid by using N2O4 and nitric acid at a low temperature of 5–10 °C in liquid phase. After esterification and dehydration MMA is obtained. However, this process does not seem to be economically favorable because the yield is not sufficient and there are some problems such that large amounts of nitric acid and NOx should be handled. In addition, an explosion accident happened during the operation in the plant. Therefore, this production was stopped in 1965.[3]

Uses

The principal application, consuming approximately 75% of the MMA, is the manufacture of polymethyl methacrylate acrylic plastics (PMMA). Methyl methacrylate is also used for the production of the co-polymer methyl methacrylate-butadiene-styrene (MBS), used as a modifier for PVC. Another application is as cement used in total hip replacements as well as total knee replacements. Used as the "grout" by orthopedic surgeons to make the bone inserts fix into bone, it greatly reduces post-operative pain from the insertions but has a finite lifespan. Typically the lifespan of methylmethacrylate as bone cement is 20 years before revision surgery is required. Cemented implants are usually only done in elderly populations that require more immediate short term replacements. In younger populations, cementless implants are used because their lifespan is considerably longer.[7] Also used in fracture repair in small exotic animal species using internal fixation.

MMA is a raw material for the manufacture of other methacrylates. These derivatives include ethyl methacrylate (EMA), butyl methacrylate (BMA) and 2-ethyl hexyl methacrylate (2-EHMA). Methacrylic acid (MAA) is used as a chemical intermediate as well as in the manufacture of coating polymers, construction chemicals and textile applications.[8]

Environmental issues and health hazards

The acute toxicity of methyl methacrylate is low. Irritation of the skin, eye, and nasal cavity has been observed in rodents and rabbits exposed to relatively high concentrations of methyl methacrylate. Methyl methacrylate is a mild skin irritant in humans and has the potential to induce skin sensitization in susceptible individuals.[9][10]

See also

References

- 1 2 3 4 5 6 "NIOSH Pocket Guide to Chemical Hazards #0426". National Institute for Occupational Safety and Health (NIOSH).

- 1 2 "Methyl methacrylate". Immediately Dangerous to Life and Health. National Institute for Occupational Safety and Health (NIOSH).

- 1 2 3 4 5 6 7 8 Nagai, Koichi (2001). "New developments in the production of methyl methacrylate". Applied Catalysis A: General. 221: 367–377.

- ↑ http://www.chemistryviews.org/details/news/2502791/New_Catalyst_for_Methyl_Methacrylate_Process.html

- ↑ William Bauer, Jr. "Methacrylic Acid and Derivatives" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH, Weinheim. doi:10.1002/14356007.a16_441.

- ↑ http://www.ingenia.org.uk/ingenia/issues/issue45/harris.pdf

- ↑ Nordin, Margareta (2001). Basic Biomechanics of the Musculoskeletal System. New York: Lippincott Williams & Wilkins. pp. 401–419. ISBN 978-0-683-30247-9.

- ↑ http://www.mpausa.org/about-methacrylates2/

- ↑ http://www.who.int/ipcs/publications/cicad/en/cicad04.pdf

- ↑ http://www.cdph.ca.gov/programs/hesis/Documents/mma.pdf

External links

- Chemical data on Chemicalland

- US Environmental Protection Agency, 1994 data

- Intox Cheminfo data

- Methacrylate Producers Association (MPA)

- National Pollutant Inventory – Methyl methacrylate fact sheet

- CDC – NIOSH Pocket Guide to Chemical Hazards